PE tarpaulin, short for polyethylene tarpaulin, is a widely used protective fabric crafted mainly from polyethylene(PE) resin, a common thermoplastic polymer. Its popularity stems from a blend of practical properties, cost-effectiveness, and adaptability, making it essential in both industrial and daily scenarios.

In terms of material composition, PE tarpaulin primarily uses high-density polyethylene(HDPE) or low-density polyethylene(LDPE). HDPE based ones offer higher tensile strength and rigidity, while LDPE variants are more flexible. Additives like UV stabilizers (to resist sun damage), anti-aging agents (to extend lifespan), and waterproofing modifiers are often added. Some heavy-duty types even have woven polyester or nylon mesh reinforcement for better tear resistance.

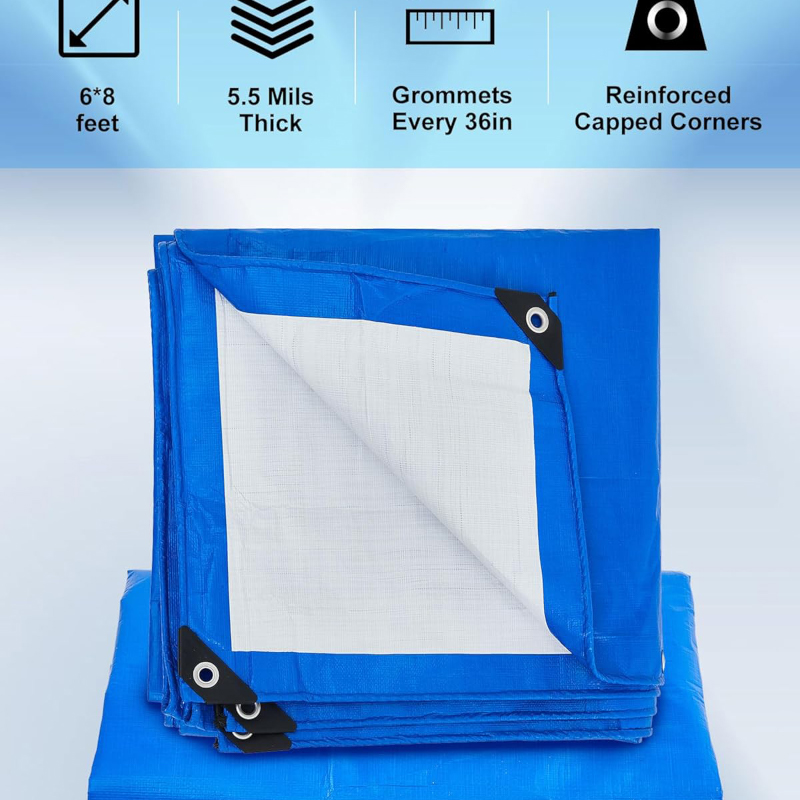

The manufacturing process involves three key steps. First, PE resin and additives are mixed, melted at 160-200℃,and extruded into films or sheets. Then, lightweight versions are cut after cooling, while heavy-duty ones get PE coated onto a woven base. Finally, edge sealing, eyelet drilling, and quality checks ensure usability. PE tarpaulin boasts excellent properties. It is inherently waterproof, blocking rain and dew effectively. With UV stabilizers, it endures sunlight without fading or cracking. Lightweight (80-300g/㎡) and flexible, it is easy to carry and fold, fitting irregular objects. It is also affordable and low-maintenance-stains can be cleaned with water or mild detergent.

Common applications include covering cargo in logistics, acting as greenhouse or hay covers in agriculture, serving as temporary roofing in construction, and being used as camping tents or car covers for daily outdoor activities. Though it has limitations like low heat resistance and poor abrasion resistance for thin types, PE tarpaulin remains a go-to choice for reliable protection.

Post time: Jan-09-2026